Components within Semiconductor Manufacturing Machinery

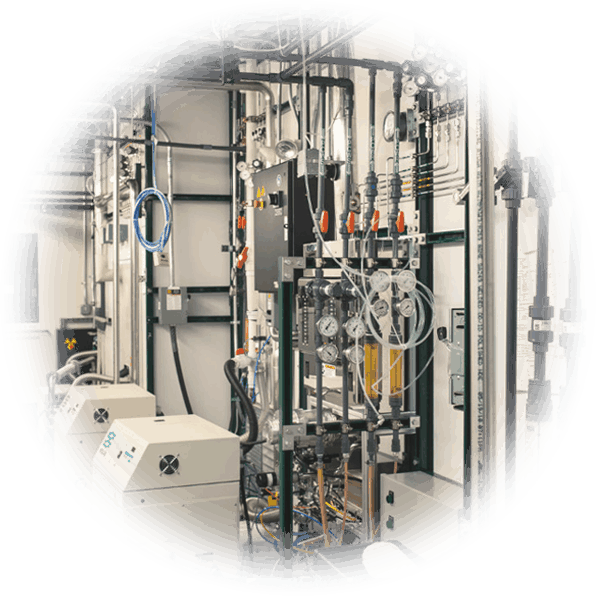

To function reliably, semiconductors must be manufactured with the utmost precision. This can be especially challenging in today’s market, where miniaturization is coupled with high-performance expectations. Using the latest deep drawn stamping technology, Hudson manufactures a variety of top-quality semiconductor manufacturing components, including:

Bellows

Bellows are precise, metal components that serve as a leak-tight seal and are designed to compress, bend, or extend to absorb angular or axial movement. These components are used in semiconductor fabrication machinery due to their ability to contain a vacuum, prevent contamination, and ensure an ultra-clean manufacturing environment. At Hudson Technologies, our deep drawn stamping capabilities allow us to create a range of conventional and welded-edge bellows, including:

Pre-clean • Orientor • Load lock • Slit • Wafer lift • Chamber lift • Vacuum valve

Common Applications for Bellows in Semiconductor Fabrication Machinery

| Slit valves |

Connectors |

Flexible couplings |

Valve stem seals |

| Actuators |

Gate valves |

Lifters |

Wafer handlers |

| Orientors |

Beam lines |

XYZ manipulators |

Torque coup;ings |

| Gas lines |

Motion feedthroughs |

Leak detectors |

Ultra high vacuum systems |

MPS Sensors and Diaphragms

With decades of experience, Hudson is pleased to offer extensive metal diaphragm manufacturing services. Using the latest deep drawn stamping equipment, we can manufacture even the most complex metal diaphragms for your semiconductor manufacturing operation.

MPS sensors and diaphragms are used by semiconductor manufacturers to sense and transmit motion between steps in the fabrication process. As a stand-alone metal diaphragm manufacturer, we have extensive hands-on experience designing and creating reliable MPS sensors and pressure transducer diaphragms used in semiconductor manufacturing.

Unique Manufacturing Considerations for the Semiconductor Industry

Semiconductor manufacturing involves converting silicon and semiconductor metals from raw wafers into integrated circuits and other electronic components. There are many factors to consider throughout the manufacturing process to ensure optimal quality and performance.

For example, this process is usually performed in a clean room environment to avoid contamination and control conditions such as temperature, humidity, dust levels, and more. Another key consideration is the manufacturing machinery itself. Semiconductor manufacturing machinery is highly specialized and must be able to achieve very high tolerances on very small parts with no errors. Using top-quality machinery components guarantees the level of precision required by the semiconductor industry.

Common Manufacturing Methods Utilized

To create the highly accurate components necessary for quality semiconductor production, Hudson utilizes a variety of specialty stamping operations, including:

When manufacturing custom semiconductor components, Hudson uses a unique combination of these processes. Our sizable facility holds more than 15,000 standard tooling products, and we are capable of creating custom tools to accommodate a variety of shape, size, and volume specifications within tight tolerances.

Semiconductor Machinery Components From Hudson Technologies

At Hudson Technologies, we are committed to producing precision machinery components for semiconductor manufacturing. We understand that semiconductor machinery components must perform with reliable, repeatable precision within exceptionally tight tolerances. No matter the size, shape, volume, or precision requirements for your semiconductor project, we have the knowledge, experience, and equipment to ensure optimal components.

Our team maintains regular communication with you throughout the process, from design and prototyping to production and testing. It is our goal to provide you with superior parts for all aspects of your semiconductor fabrication operation.

To learn more about our semiconductor component manufacturing capabilities and other deep drawn stamping services, contact our experts today or request a quote.